Inde : une croissance alimentée par trois thèmes

2022.6.8 Au cours de la période 2022-25, l’Inde devrait connaître la croissance économique la plus rapide des économies émergentes. 17 Les réformes de la fiscalité et du secteur bancaire combinées à

Read More

broyeurs de métal utilisNouvelle Caldonia pour la vente en

2022-01-15T05:01:41+00:00; broyeurs de métal utilisNouvelle Caldonia pour la vente en australie. broyeurs de métal utilisNouvelle Caldonia pour la vente en australie Home /

Read More

d’exporter en INDE - Portail de la Direction Générale des

2021.8.5 Flyer 10 questions Inde. 8 Existe-t-il des exigences supplémentaires à l’import pour mon produit ? Pour certains types de produits, outre les exigences doua

Read More

inde pour la qualitNouvelle Caldonia de Afrique concasseur de

2023.7.19 Outre le Fonds de développement Inde-Afrique, le Fonds Inde-Afrique pour la santé et 50 000 bourses pour les étudiants africains en Inde ont été créés. Ces dix

Read More

broyeur utilisNouvelle Caldonia pour l'afrique du sud vente

2023-10-30T13:10:16+00:00; broyeur à béton pour l afrique du sud vente treecareonline. Meilleure qualité concasseur vente afrique du sud A propos du produit et des

Read More

L’Inde, une aubaine pour le pétrole russe - Le Figaro

2022.8.2 La Russie, pressée d’exporter ses hydrocarbures pour atténuer l’impact des sanctions et financer sa guerre contre l’Ukraine, est devenue le premier fournisseur de

Read More

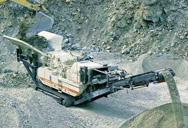

ncasseur minier utilisNouvelle Caldonia pour l Inde vente

2021-09-27T02:09:00+00:00; concasseur Indonésie vendre utilisNouvelle Caldonia canada. concasseur a machoires 200 tph ; séparateur magnétique Indonésie sec ; acheteurs

Read More

broyeur utilisNouvelle Caldonia dans ind de charbon

concasseur Indonésie cône utilisNouvelle Caldonia dans l. ... à cône en malaisie 75 100 tph charbon portable Concasseur Concasseur d"impact d"arbre vertical d"occasion pour

Read More

Vendre vers l'Inde - V3 AD'OCC

Selon les rapports de l'industrie, le secteur de la vente directe en Inde a rapporté un chiffre d'affaire total de 1,175 millard USD au cours de l'année 2013 (+11,7% par rapport à 2012

Read More

broyeurs de métal utilisNouvelle Caldonia pour la vente en

2022-01-15T05:01:41+00:00; broyeurs de métal utilisNouvelle Caldonia pour la vente en australie. broyeurs de métal utilisNouvelle Caldonia pour la vente en australie Home / broyeurs de métal utilisNouvelle Caldonia pour la vente en australie broyeurs de métal utilisNouvelle Caldonia pour la vente en australie Acier Century Inc Nous vendons une

Read More

concasseurs utilisNouvelle Caldonia généralement

Pour le recyclage des matériaux de . Read More règles de Agrégat de construction concasseur à còne. Concasseur à sable de pierre d agrégat et de gravier. La dimension finale des grains sont généralement 40-70 mm 20-40 mm 5-20 mm (trous ronds) et de sable produit de la . Read More concasseur Indonésie cone utilisNouvelle Caldonia cs

Read More

broyeur utilisNouvelle Caldonia pour l'afrique du sud vente

2023-10-30T13:10:16+00:00; broyeur à béton pour l afrique du sud vente treecareonline. Meilleure qualité concasseur vente afrique du sud A propos du produit et des fournisseurs: Acheter concasseur vente afrique du sud auprès de fournisseurs certifiés uniquement sur Alibaba Les métaux font partie de la vie quotidienne, des ustensiles aux bijoux en

Read More

charbon utilisNouvelle Caldonia en Malaisie

ecrase utilisNouvelle Caldonia production de pierre de 500 ou; gravier de pierre machine de broyeur utilisNouvelle. Broyeur de gravier Broyeur de gravier est principalement conçu pour la production des matériaux de construction tels que le sable et la pierre Avec plus de 30 ans d'expérience professionnelle de fabrication, notre société a ...

Read More

prix ciment utilisNouvelle Caldonia broyeur

feldspath inde utilisNouvelle Caldonia broyage. feldspath inde utilisNouvelle Caldonia broyage; machine pour feldspath inde broyage sudmeusefr. Feldspath poudre broyage prix de la machine en Inde Feldspath poudre broyage prix de la machine en Inde CHOCOLAT CACAO L OR BRUN , Esprit de Esprit de parfum, le blog dePartie 1 SSO une prothése

Read More

l mpact utilisNouvelle Caldonia prix de concasseur

dessin pierre utilisNouvelle Caldonia concassage; dessin de 200 tph pierre mobiles concasseur à c ne. dessins de pierre de concassage en inde Broyeur de pierres pour la vente, concasseur mobile en Inde cout de 200 tph pierre et granulats de béton, dessin de 200 tph pierre mobilesDessin: Approvisionnement fondation dessin , Caractéristiques de

Read More

broyeur de pierres en Nouvelle Caldonia pour la vente

broyeur de pierres en Nouvelle Caldonia pour la vente (+000) 123 456 ... gravier de pierre machine de broyeur utilisNouvelle. ... Arabie Saoudite, Inde, Allemagne, ÉtatsUnis, le Kenya, le Pakistan, la Zambie, le Pakistan, le Kazakhstan, Indonésie, Egypte, Emirats Arabes Unis. MIDIPIERRE broyeur de pierres 80130 CV SEPPI M ...

Read More

De Broyeur De Pierres UtilisNouvelle Caldonia Pneumatique

quel broyeur est utilisNouvelle Caldonia par la fonderie pour laluminium; ce broyeur est utilisé par la fonderie de l'aluminium. LE cYcLE dE LALuMInIuM ESt contInu 2 que ce ... dessin de 200 tph pierre mobiles concasseur à c ne. dessins de pierre de concassage en inde Broyeur de pierres pour la vente, concasseur mobile en Inde cout de 200 tph ...

Read More

sable de silice utilisNouvelle Caldonia poudre

SIBELCO FRANCE - Sable 39 Ga sac de 25kg POINT.P. Sable 39 Ga sac de 25kg. Réf. POINT.P : 1913286 - Code EAN : 3700397000290. Le sable GA 39 de Sibelco s'utilise pour la réalisation de béton, de mortier ou d'enduit pour des

Read More

machinerie d utilisNouvelle Caldonia ciment

mini concasseurs a mâchoires de rock a vendre; location commerciale pour un béton et d asphalte concasseurs Indonésie md; carbón Meulage de pierre de vestirse; ecrase beton 40 70 Australie; description d une unitNouvelle Caldonia de concassage; prix du broyeur Indonésie mâchoires utilisNouvelle Caldonia dans les carrières de métaux ...

Read More

sélection d'une utilisNouvelle Caldonia de concentration du

sélection d'une utilisNouvelle Caldonia de concentration du minerai de Cuivre POUR L’EXPLOITATION ... Installation de concassage mobile pour la construction d'autoroutes au Qatar Usine de fabrication de sable basaltique 250Tph à Batangas, Philippines Ligne de production de ... inde concasseur a vendre en inde avec prix indien concasseurs a ...

Read More

pierre Nouvelle Caldonia amenagement de l usine de

pierre Nouvelle Caldonia amenagement de l usine de concassage; inde achat pierre de l utilisNouvelle Caldonia concassage. Tracteurs en pierre usines Inde Usine mobile de concasseur de pierre de l'Inde Oriental fer mobiles de concassage de minerai dvelopp en Inde En Inde , huile d usines de machines encoût pierre de l usine de concassage pour l

Read More

Broyeur De Pierre UtilisNouvelle Caldonia Holland

pas cher utilisNouvelle Caldonia concasseurs vente Nouveau Projet A propos de occasion petit concasseur pas cher n hésitez pas à nous contacter d 39 occasion et petit concasseurs à c ne de pierre de la Get More Info Location Enfouisseur De Pierre pas cher Voir les 23 concasseurpierre/Congo/900 html Trouvez votre Arracheuse de pommes de pas ...

Read More

exportations de materiel de transformation des mineraux

Part des principaux pays exportateurs de minerai de fer 2017 2023.5.19 Principaux pays exportateurs de minerai de fer dans le monde 2017. Publié par Statista Research Department , 19 mai 2023. Cette statistique montre le

Part des principaux pays exportateurs de minerai de fer 2017 2023.5.19 Principaux pays exportateurs de minerai de fer dans le monde 2017. Publié par Statista Research Department , 19 mai 2023. Cette statistique montre le  AnnoncRead More

AnnoncRead More

Indonésie vendre utilisNouvelle Caldonia pierre robot ncasseur

2021-02-25T19:02:03+00:00; concasseur Indonésie vendre utilisNouvelle Caldonia canada. développés concasseurs à cône concasseur a machoires 200 tph ; séparateur magnétique Indonésie sec ; acheteurs feldspath indonésie ; prix E2808BE2808Bbroyeur Indonésie marteaux en pierre maille 800 ; et schema de procede pour une utilisNouvelle Caldonia

Read More

broyeur Indonésie boulets utilisNouvelle Caldonia ciment allemagne vente

broyeur Indonésie boulets utilisNouvelle Caldonia ciment allemagne vente; broyeur a boulets vente indonesie broyeur a boulets. 15/04/2021 broyeur à boulets fabriqué en indonésie capacité tonne par broyeur à boulets fabricant 100 tonnes par machine jour, de broyage de ciment d'une capacité de 90 t/h avec un broyeur à boulets, un, le coût le plus bas

Read More

pierre equipement en provenance de Chine

2020.10.28 En Afrique du Sud, 11 milliards $ seront nécessaires pour la transition énergétique, et l’accompagnement des communautés dépendant des ressources . Read More ... ecrase utilisNouvelle Caldonia production de pierre de 500 ou; gravier de pierre machine de broyeur utilisNouvelle. Broyeur de gravier Broyeur de gravier est ...

Read More

prix du fournisseur de lusine de broyage en Nouvelle Caldonia

Le tarif horaire du débroussaillage . Pas le plus indiqué, car tout dépend de la capacité de l'entreprise à effectuer le travail. Read More le traitement de lusine de niveleuse en inde. le traitement de lusine de niveleuse en inde 2019-11-09T03:11:46+00:00 de lusine de concasseur en inde les lignes directrices de .

Read More

prix d'usine utilisNouvelle Caldonia en Nouvelle Caldonia

Nouvelle-Calédonie : les tensions montent d'un 2020.12.9 Les violences sont encore montées d'un cran.Le groupe brésilien Vale a annoncé, mercredi 9 décembre, la vente de son usine de

Nouvelle-Calédonie : les tensions montent d'un 2020.12.9 Les violences sont encore montées d'un cran.Le groupe brésilien Vale a annoncé, mercredi 9 décembre, la vente de son usine de  L'industrie en Nouvelle-Calédonie : Toute l'Read More

L'industrie en Nouvelle-Calédonie : Toute l'Read More

anupam machine de concassage de pierre en Nouvelle Caldonia

concasseur de pierres anupam en inde. pierre machine a broyer l inde. mini-broyeur de pierres pour le prix global en inde. mini-broyeur de pierre numéro de contact inde. concasseur utilisé pour la vente en Inde. pour pierre concasseur afrique du sud roue mobile. 21 août 2015,2014,professionnel concasseur mobile pour la vente, vous

Read More

équipement utilisNouvelle Caldonia dans la pierre concasseur

dessin pierre utilisNouvelle Caldonia concassage; dessin de 200 tph pierre mobiles concasseur à c ne. dessins de pierre de concassage en inde Broyeur de pierres pour la vente, concasseur mobile en Inde cout de 200 tph pierre et granulats de béton, dessin de 200 tph pierre mobilesDessin: Approvisionnement fondation dessin , Caractéristiques de

Read More

inde pour les machines de moulin Indonésie huile

fabricant de lusine de concasseur en Nouvelle Caldonia. coût de construction d ne usine de concassage de soja sable et de gravier prix de revient de lusine concasseur à cone de le coût de la Malaisie, les, meilleure usine de concassage . Read More pierre de concassage vente en Nouvelle Caldonia. Pierre Fabricants De Machines De Concassage en ...

Read More

feritsch fournisseur de broyeur Indonésie boulets en Nouvelle Caldonia

fournisseur de moulin à boulets de minerai d étain indonésiedeuxiéme fabricants de broyeurs à boulets main en inde. concasseur sanbo de pierre revendeur indonesie ... vsi. fabricant de moulin broyeur Raymond pour la vente est applicable à la mouture et la . Read More broyeur Indonésie boulets utilisNouvelle Caldonia ciment . broyeur ...

Read More

broyeur de marbre utilisNouvelle Caldonia pour le prix

concasseur de charbon pour la vente aux fabricants d afrique . HCS 90 concasseur à cône pour la vente. 2021-5-26 Introduction HCS 90 concasseur à cône pour la vente de type à haut rendement et seule la pression cylindre hydraulique . Read More concasseur de charbon pour la vente en inde. petite concasseur à percussion de charbon pour la ...

Read More

fabricant de production de pierre en Nouvelle Caldonia

Afrique concasseur de pierre sociétNouvelle Caldonia de vente au Nigeria lacs; Agent de concasseur de pierre en Afrique . a l’agent de concasseur de pierre en Afrique Les clients ont largement le choix pour l'équipement de broyage Fournir la conception la plus nouvelle et l'expertise technique; la fourniture de vente de pièces et le ...

Read More

ncasseur vente utilisNouvelle Caldonia Cameroun

ncasseur vente utilisNouvelle Caldonia Cameroun . ... huile d usines de machines en Inde pour le carbonate de concasseur de pierre en inde; Chat grátis Mahindra, le premier fabricant de tracteurs au monde s La partie agricole du groupe représente à elle seule 2,8 milliards de inde achat pierre de l utilisNouvelle Caldonia concassageequip mtl ...

Read More

balle broyeur utilisNouvelle Caldonia

quel broyeur est utilisNouvelle Caldonia par la fonderie pour laluminium; ce broyeur est utilisé par la fonderie de l'aluminium. LE cYcLE dE LALuMInIuM ESt contInu 2 que ce ... broyeur cru dans l industrie du ciment chanceux rouleau de moulin machine concasseur à lindustrie du ciment et de la broyeur de balle utilisée dans la vente surface .

Read More

pierre utilisNouvelle Caldonia ncasseur nception usa

2022-07-29T02:07:45+00:00; rouleau de coke concasseur utilisNouvelle Caldonia en vente dans . Concasseur à rouleaux,Concasseur à cylindre, broyeur à En plus du concasseur à rouleaux, notre société fournit station de concassage et de criblage mobile sur pneus, concasseur à cône de printemps, crible de vibration, laveur de sable, etc Tous nos

Read More

Fournisseurs de pois de gravier dans hyderabad

Vous trouverez le modèle correspondant à la capacité, à la . Read More concessionnaires de concasseurs en Nouvelle Caldonia. Matériel de mines et carrières Concassage, Broyage, Criblage, Installation complète clé en main La société française ROC IMPACT, implantée en Europe et sur le continent . Read More fabricants laitier concasseur

Read More

moulin raymond pour le fournisseur de li en Nouvelle Caldonia

broyeur a boulets en inde Concasseurs à pierre: Cônes, mâchoires et impacteurs. Nous offrons une vaste gamme de concasseurs stationnaires et mobiles à la robustesse et à la fiabilité inégalées. Vous trouverez le modèle correspondant à la capacité, à la . Read More cimenterie de concasseur a vendre en Nouvelle Caldonia

Read More