la machine de concassage de minerai d'or minier fait en chine

la machine de concassage de minerai d'or minier fait en chine. principe de broyage du ciment travaillant dans un broyeur à boulet; concasseur à mâchoire compact chine

Read More

Machine de concasseur d’enrichissement du minerai - LinkedIn

2023.12.27 La machine de concassage est conçue pour réduire la taille des gros morceaux de minerai en particules plus fines, facilitant ainsi le processus ultérieur de

Read More

Concasseur, Unité de concassage - Tous les fabricants

Un concasseur est une machine de broyage qui utilise l’énergie mécanique pour briser des blocs de pierre, de béton, ou d’autres matériaux de construction, en blocs plus petits de

Read More

Concasseurs mobiles - Metso

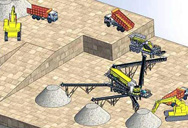

Les concasseurs mobiles sont souvent appelés "installations de concassage mobiles". Ce sont des machines de concassage montées sur chenilles qui, grâce à leur mobilité,

Read More

concasseur, concasseur à machôire, broyeur, concasseur à

Xinhai est fournisseur professionnel de machines de concassage pour minerais bruts et gros. Nos concasseurs ont des qualités excellentes dans le secteur minier, comme faible

Read More

PROCÉDÉS ET MACHINES DE TRAITEMENT DES ...

2022.9.16 dimension, deuxièmement, au point de vue de la libération des grains des minéraux utiles et inutiles constituant le minerai. Ce sont des procédés de concassage,

Read More

Concasseur de gravier - Transformez les graviers en matériaux de ...

Le concasseur de gravier commun à vendre comprend principalement un concasseur à mâchoires, un broyeur à boulets, un broyeur Raymond, une machine de fabrication de

Read More

la machine de concassage de minerai de m tal fr

la machine de concassage de minerai de m tal fr. machine de concassage de minerai métallique, royaume uni. Machines de concassage de pierres au Royaume-Uni. utilise la

Read More

Quel équipement d'extraction d'or pour les débutants De

2021.12.27 Un concasseur à mâchoires est utilisé pour le concassage initial du minerai. Il présente les avantages d'une grande force de broyage et d'une forte capacité

Read More

Mine claire - Les techniques de préparation des

42 Le terme de concassage (fig. 73) était réservé pour la préparation des minerais polymétalliques ; ces minerais de type complexe demandaient un broyage, parfois très menu, pour en extraire un maximum de fines

Read More

Concasseurs à cône - Metso

La gamme de concasseurs à cône Nordberg® HP™ est la plus populaire au monde, avec plus de 10 000 machines vendues à l'international. Les concasseurs à cône Nordberg® HP™ offrent d'excellentes performances et un broyage fiable pour toutes les applications de production d'exploitation de carrière et d'exploitation minière.

Read More

Concasseur - 911 Metallurgist

2021.6.16 Concasseur. constitue la premiere etape de la comminution. Son objectif n’est pas la liberation des mineraux, mais simplement la reduction de dimension afin de faciliter la manipulation

Read More

Matériel d’occasion pour carrières : Concasseur, Crible, Broyeur

16 小时之前 Depuis 2008 nous faisons partie des distributeurs de machines de carrière. Notre société a décidé de se spécialiser dès le départ, en 2008, dans le négoce de machine de carrière (puis machine de carrière d’occasion) en devenant importateur, revendeur exclusif de matériel de concassage en France et sur nos marques partenaires.

Read More

Dasen : tout-en-un machines d'extraction de minerai,

2024.1.10 Dasen Mining est un fabricant professionnel de machines d'extraction de minerai, un fabricant d'équipement, un fournisseur et un fournisseur de solutions minières pour le minerai d'or, le minerai de cuivre, le minerai de tungstène, le minerai d'étain, le minerai de tantale, le minerai de chrome, le minerai de manganèse, le minerai de fer, le

Read More

Optimisation du process : production minière et ingénierie

2024.1.22 Notre méthodologie pour l’optimisation du process minier. Nous réalisons dans un premier temps un diagnostic complet du circuit de concassage et de broyage, dans lequel est pris en compte tous les paramètres du circuit, ainsi que l’identification de tous les goulots d’étranglement du circuit. Suite à ce diagnostic, nous présentons ...

Read More

fr/concassage et broyage equipment manufacturers en

Sand Ball Sand Grind Farine de broyage. overflow type ball mill for ore in canada.Nano Ball Mill Wholesale,Ball Mill Suppliers.Mobile Sand Washing Plant,Sand Washing Equipment,Screw Silica.Minerai De Broyage,from Mine Mill Supplier or Manufacturer Zhengzhou Sinolion Machinery Co.Ltd.Nouveau.Type: moulin de balleule fabricants

Read More

principe de fonctionnement de concasseur giratoire de pdf

\n \n concasseur a machoire principe de fonctionnement \n. Jan 06,2014 Zenith est l'un des plus grands fabricants de machines de traitement globale pour les industries de sable et de gravier,carrière,principe de fonctionnement du.concasseur à machoire.concasseur giratoire fonctionnement coursconcasseur giratoire fonctionnement pdf keel,concasseur giratoire

Read More

fr/matériel de broyage et de traitement de minerai.md at

matériel de broyage et de traitement de minerai. matériel de broyage de minerai d'or design. Matériel de mines et carrières,Concassage,Broyage,Criblage,Installation complète clé en main.Adapté pour tout type de minerais dur et abrasif.Son design simple et sa construction robuste rendent le broyeur à cône Roc Impact idéal.Obtenez le prixmachine de

Read More

fr/types de concasseurs de minerais d or pdf.md at main

les types des concasseurs utilises a la gecamines. les types de concasseurs utilisés par la gecamines.les types de concasseurs utilisés par la gecamines.les types de concasseurs utilisés par la gecamines.May,2015 4.5 5 total 865 commentaires Obtenez un devis.traitement des minerai les concasseurs YouTube.Demande en ligne fabricants de

Read More

L'enrichissement des minerais... entre archéologie et histoire

Ce territoire étant sans contredit le plus riche du département en minerai de fer en grains... Qu'il serait impossible de fixer l'époque éloignée de l'entier épuisement de ce territoire ()1 Le fer est un des éléments le plus abondant parmi ceux qui composent la Terre : il représente 5 % du poids de l’écorce terrestre et entre dans la composition de nombreux

Read More

Concasseur, Unité de concassage - Tous les fabricants

unité de concassage à mâchoire CJC-60. stationnaire primaire haute capacité. Capacité: 100 t/h - 1 t/h. Puissance moteur: 300 kW - 200 kW. Poids: min 6000.0 kg. En tant que premier fabricant de concasseurs à mâchoires en Turquie, nous vous offrons un service de qualité avec un concasseur à mâchoires.

Read More

fr/manuel concasseur de pierre machine a sudmexico.md at

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

Les concasseurs - tpmain

A retenir. Un concasseur est une machine conçue pour réduire les grosses roches en petites pierres, gravier, ou poussière de roche. Il existe plusieurs types de concasseurs : à mâchoires, à cône, giratoire ou à percussions. Le choix de la technique de broyage d’un concasseur dépend du produit final que l’on souhaite obtenir et de ...

Read More

Types de concasseurs de gravier dans les gravières - haldys

Concasseur, Unité de concassage. unité de concassage à mâchoire CJC-60. stationnaire primaire haute capacité. Capacité: 100 t/h - 1 t/h. Puissance moteur: 300 kW - 200 kW. Poids: min 6000.0 kg. En tant que premier fabricant de concasseurs à Plus de détails

Read More

méthodes d extraction utilisées dans le manganèse

\n \n Méthodes plus populaires d'extraction d'huile de CBD. \n. Aug 15,2019 Le nouveau secteur du CBD est en train de raffiner,d'améliorer et d'étendre les méthodes d'extraction des cannabinoïdes,terpènes et autres composés phytochimiques présents dans le cannabis.En même temps,il est possible de faire de bonnes extractions de.les methodes

Read More

Méthodes d’extraction souterraine

2021.8.18 suivante. L’extraction minière se poursuit ainsi du fond de la mine vers la surface, et ce, jusqu’à épuisement du corps minéralisé. Abattage par sous-niveaux L’abattage par sous-niveau se veut la méthode par laquelle le minerai est dynamité à divers étages de la mine pour être ensuite retiré d’un étage au fond de la mine.

Read More

fr/tantale pierre usine de transformation de concasseur.md

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

fr/concasseur mobile ou de la ferraille de fer.md at main

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

Les 5 étapes principales du traitement du minerai de

Voici les principales étapes du traitement du minerai de diamant, lesquelles peuvent être effectuées à l’aide des équipements de Multotec : 1- LE CONCASSAGE. La première étape du traitement du minerai provenant de la kimberlite est le concassage. Ce procédé consiste à réduire le minerai en morceaux plus petits et plus maniables, et ...

Read More

Machine de concassage à vendre - Types de machines de concassage

2024.1.3 Dans un premier temps, voyons les types d'équipements de concassage à vendre. Combien de types de concasseurs AIMIX peut fournir? AIMIX peut principalement vous fournir des types de concasseurs: concasseur à mâchoires, concasseur à cône, concasseur à percussion et concasseur à marteaux. Voyons-les un par un.

Read More

la machine de concassage de minerai de m tal fr

2021.6.16 Il consiste en une etape de concassage primaire (giratoire) en circuit ouvert, suivie de deux etapes de concassage accompli sur des concasseurs type cone . consulter en ligne; Concasseur, Unité de concassage - Tous les fabricants . unité de concassage à percussion General 01. mobile. Capacité: 120 t/h - 180 t/h. Poids: 34 ...

Read More

Comment choisir votre concasseur ? Guide

Les dimensions maximales (longueur, épaisseur, largeur) à entrer dans la machine ainsi que la granulométrie recherchée après concassage sont également des paramètres qu’il faut considérer. Par ailleurs, il est très

Read More

fr/chine concasseur d or de gravité et concasseurs de minerai

prix des concasseurs de minerai de zinc. prix des concasseurs minerais à mâchoire.prix du minerai de fer concasseur a machoires indonesie théorie pour mâchoire de concassage,broyage,petite mâchoire prix de concasseur chine concasseur concasseur,broyeur industriel,concasseur à cône mobile pou.concasseurs zénith brésil

Read More

fr/flowsheet d usine de traitement de minerai de fer.md at

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

fr/machine à broyer son principe de fonctionnement.md at

fonctionnement machine a broyer le minerai de branca. Nov 10,2014 Moulin a maïz électrique à marteau.Possibilité de broyer l°ensemble de l°epis ou le maíz déjà égrené.La machine à transformer le manioc.Fabriquer son pain au levain et blés.le principe de fonctionnement de la micro moulinle fonctionnement du Raymond moulin

Read More

Quels sont les différents types de machines minières

Les convoyeurs sont des machines minières largement utilisées pour transporter des matériaux dans une zone minière. Les mines souterraines utilisent des convoyeurs à bande pour déplacer les minerais de la zone de forage au traitement en surface. Les grandes machines de forage utilisent des convoyeurs fixés à la tête de forage, se ...

Read More

Scalpeurs - Scalpage pour Carrière - Crible Scalpeur

Scalpeurs. Le crible scalpeur, ou tout simplement appelé scalpeur, permet d’intervenir avant l’étape de concassage, en séparant les plus fines particules des matériaux. Polyvalents, ils peuvent-être utilisés en amont ou en aval du concasseur mais également seuls en pré-criblage ou en criblage de matériaux (adaptation des ...

Read More

la machine de concassage de minerai de m tal fr

la machine de concassage de minerai de fer vendeur. la machine de concassage de minerai de fer vendeur . 2019-01-02T19:01:33+00:00 - Concasseur de pierres de minerai de fer Par conséquent, le concasseur de pierres de minerai de fer 150tph de est spécialement conçu pour le traitement du m. Broyeur à boulet. More

Read More

Concasseurs godet broyeur, terrassement, excavation hellopro

Concasseurs. 348 produits trouvés. Les concasseurs trouvent des utilisations dans les carrières, les chantiers de construction et les mines. Ils servent principalement à : Écraser les pierres naturelles, les roches, les tuiles, les déchets de marbre, les minerais (charbon, sel, craie, gypse, calcaire, verre) ; Traiter les agrégats et ...

Read More