crusher/sbm animation of three stage coal crushing in

Contribute to yunan88/crusher development by creating an account on GitHub.

Read More

Energy Evolution and Coal Crushing Mechanisms Involved in Coal

2023.12.16 The relationship between coal crushing energy and particle size distribution after crushing conforms to the new surface theory, which states that the

Read More

Optimal operation of coal conveying systems assembled with crushers ...

2017.7.15 Concerning the coal conveying system of a coal-fired power plant, this paper takes the belt conveyors and crusher as a whole for energy efficiency optimization.

Read More

The flowchart of crushing process with one-stage

According to the results of the test, capacity values in the crushing process of a one-stage reduction for Soma, Kale, and Isparta coal samples were 180 kg = h, 99 kg = h, and 90 kg = h ...

Read More

An analysis of impact load and fragmentation dimension

2023.12.4 This research delineates the energy dissipation characteristics in coal crushing under impact loads, leveraging the capabilities of Separated Hopkinson

Read More

sbm/sbm raymond coal mill animation.md at main dihog/sbm

Contribute to dihog/sbm development by creating an account on GitHub.

Read More

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016.3.10 Crushing Plant Flowsheet Design-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding

Read More

Optimization of particle size distribution in circulating fluidized ...

2019.6.15 The results were applied in optimizing an industrial-scale crushing system and two-toothed roll crusher of a coal gangue-fired power plant. Investigations

Read More

Chapter 75 Operation and Maintenance of Coal

2023.2.13 Coal screen and coal crusher are the key equipment of coal conveying system in thermal power plant (Lang 1998;Zhaoetal2001a, b). Coal conveying system

Read More

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018.1.1 The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend the operational behavior of the coal pulverizer unit for good performance of the boiler and overall coal power-plant. This paper describes the first principle based energy and mass ...

Read More

mill/sbm moving animated pitcures of ball mill machines.md

Ball Mill Coal Pulverizer Animation Pictures Moving Sale Ball Mill Coal Pulverizer Animation Pictures Moving Sale.3d animation of a gyratory cone crusher crushing sale cone crusher assembly smarter computing blog spare parts and consumables of cone crusher ultratech to training through marketing tool for sales support the 3d animation of.

Read More

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016.3.10 Crushing Plant Flowsheet Design-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

Read More

PENERAPAN RISK MANAGEMENT DENGAN METODE ...

Metode : Kerangka pemikiran penelitian ini adalah potensi bahaya dari segala aktivitas di area Coal Crushing Plant (CCP) dimana di dalamnya terdapat resiko kecelakaan kerja. Untuk mencegah terjadinya kecelakaan yakni dengan penerapan risk management dengan metode Job Safety Analysis (JSA) .

Read More

1.6 FUEL HANDLING SYSTEM (COAL HANDLING) - RCET

2021.9.5 ROHINI COLLEGE OF ENGINEERING TECHNOLOGY ME8792 POWER PLANT ENGINEERING Advantages of belt conveyor: (1) Its operation is smooth and clean (2) It requires less power as compared to other types of systems. (3) Large quantities of coal can be discharged quickly and continuously. (4) Material can be transported on moderate

Read More

From coal, a new source of rare earths - Chemical

2018.7.8 The pilot plant is expected to process 0.5 to 1.0 metric tons of coal ash per day, generating at least 50 g of concentrate containing more than 10% rare earths by weight.

Read More

Sustainability Free Full-Text Study on Co-Pyrolysis of Coal

2023.10.30 In this paper, the optimal process conditions for coal–biomass co-pyrolysis were obtained through pyrolysis experiments. The results show that under the condition of the pyrolysis temperature of 500 °C, the pyrolysis oil yield and positive synergistic effect reach the maximum, and the ratio of coal to biomass raw materials is

Read More

Construction and application of a high precision 3D

2021.11.1 The high-precision 3D simulation model for geomechanics of a complex coal seam is the necessary premise for the research on intelligent shearer and unmanned mining. However, at present, a ...

Read More

Coal Crusher Types- Impact Double Roller Crusher - AIMIX

Once the material moisture content is more than 8%, the traditional crusher will be blocked and the motor will be burned. Fortunately, Aimix’s coal crushing and screening plant can solve the problem. The biggest advantage of Aimix’s coal crusher is that it can also have normal production even on rainy days.

Read More

Schematic description of the crushing plant, (1)

This method simulated the complete crushing process of the cone crusher and realized loop optimization. Moreover, researchers have proposed the empirical model (Eloranta and Evertsson, 2006), the ...

Read More

sbmchina/sbm powerpoint on coal crushing and grinding

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Read More

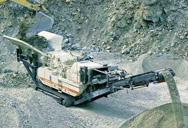

What are the risks of the Coal Crushing Plant? – LigaAsuransi

2022.6.10 Mobile coal crushing plant can be transported easily with a single truck and provides cost advantage and convenience to companies in short-term or mobile projects. Stationary Crushing Plant. Although it has the same function as the mobile crushing plant, the difference is that the stationary crushing plant is built on a fixed body.

Read More

Appendix E: Coal Mining and Processing Methods Coal:

The unit processes in coal preparation plants vary, but the following sequence of steps is typical. Crushing and breaking. Run-of-mine coal must be crushed to an acceptable top size for treatment in the preparation plant. Typical crushing and breaking devices are feeder breakers, rotary breakers, hammer mills, and roll crushers. Sizing ...

Read More

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023.10.8 The selection of coal crushing equipment mainly depends on the input size of raw coal, the moisture of the coal, and the production scale (output) of the plant. Of course, the output size and the final use of coal also need to be considered, such as 0-25 mm for gas furnaces, 8-25 mm for steam locomotives, 6-25 mm for industrial furnaces,

Read More

GitHub

AutoCAD SketchUp 專業課程 Coal Crushing Plant Design In Autocad Autocad drawing diagram coal crushing plant solution cad diagrams for hammer crushers pdf caiman mining hammer crusher drawing cad file iso 10628 flow diagrams for process plants general rules pdf. coal crushing plant diagram iqsa.co autocad drawing diagram coal crushing ...

Read More

Energies Free Full-Text Evaluation of the Energy

2022.7.29 This study evaluates: (a) The effects of l/d on the energy consumption law and fractal characteristics of coal crushing; (b) The effects of l/d and stress balance on energy dissipation; (c) The effects of l/d and energy consumption density on the fractal characteristics of coal crushing. The findings under different l/d are as follows: (1) The ...

Read More

Sustainability Free Full-Text Research on the Physical and

2023.8.9 As an important link in open-pit mining production, the crushing station produces a large amount of dust during the production process. Dust has the characteristics of a wide spread area, great harm, and difficult governance. Therefore, dust control has become a key issue that needs to be solved in open-pit mining. In this article, we assess

Read More

crusher/sbm animation of three stage coal crushing in

Contribute to yunan88/crusher development by creating an account on GitHub.

Read More

Energies Free Full-Text Technique to Investigate

2021.11.4 The operating costs of breaking coal particles into fine powder, to achieve optimum combustion for the boilers in a power plant, are made up of power input to carry on an energy intensive comminution

Read More

Coal Pulverization System: Explosion Prevention and

2017.1.5 The explosibility of the coal used in the system was measured, and the hazards of the process were analyzed. Explosion prevention and protection methods ap-plied in the process were described including atmospheric inerting, powder inerting and venting. Atmospheric inerting is the main method to prevent dust explosions in this proc

Read More

Pulverizers 101: Part I - POWER Magazine

2011.8.1 In essence, the performance of a pulverizer is a delicate balancing act between the HGI, fuel fineness, and throughput. 1. A typical MPS-89 pulverizer found in many coal-fired power plants ...

Read More

Crushers - All crusher types for your reduction needs - Metso

Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other.

Read More

Crusher - an overview ScienceDirect Topics

9.3.1 Coal Jaw Crusher. This is used for crushing and breaking large coal in the first step of coal crushing plant applied most widely in coal crushing industry. Jaw crushers are designed for primary crushing of hard rocks without rubbing and with minimum dust. Jaw crushers may be utilized for materials such as coal, granite, basalt, river ...

Read More

Coal Handling Plant Layout - Thermal Power Generation

2020.5.13 The major advantage of this type is that the coal can be carried directly into the powerhouse up to the point of consumption. 5. Transportation by Pipeline. In this method, the coal in the form of slurry is directly supplied from the remote mines to the strategically located thermal power plants through pipelining.

Read More

Crusher Icon royalty-free images - Shutterstock

2024.1.23 Oil Production Plant Collection Icons Set Vector. Olive Tree And Oil Bottle, Elevator And Crusher, Brazier And Sorting Line, Press And Refiner Black Contour Illustrations ... Coal Crushing at Belt Conveyor to Jetty Stockpile Sebakis North Kalimantan. Coffee , Thin Line and Pixel Perfect Icons. wood crusher, spanner, sawdust, Board, gear ...

Read More

Coal Beneficiation Process Diagram - 911 Metallurgist

2016.4.12 Remarks on Coal Beneficiation Process and Diagram. “Sub-A” Coal Flotation Systems have been successful for recovery of both coarse and fine coal. It is important, however, to employ a two-stage circuit for maximum efficiency in saving the plus 28 mesh fraction which is normally the most difficult to float.

Read More